|

|

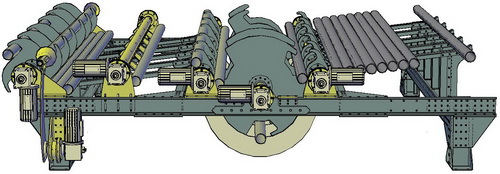

Tube

Galvanizing

Machine

Model

TGS162 |

Technical

Specifications:

input nit

input tube with rate

of one tube each 2.5 sec

tubes from 1/2 inch to 4 inches

tray area accepts au to 160 cm of tube diameters

loading system

loading unit to load

tubes from input tray to dipping system with rate one tube each 2.5

sed.

start position must be considered

unloading system

unloading unit to

unload tubes from dipping system to output tray with rate one tube

each 2.5 sed.

start position must be considered

exit system

exit unit to unload

tubes from output tray to blowing system and next station with rate

one tube each 2.5 sed.

start position must be considered

loading system

loading unit to load

tubes from input tray to dipping system with rate one tube each 2.5

sed.

start position must be considered

unloading system

unloading unit to

unload tubes from dipping system to output tray with rate one tube

each 2.5 sed.

start position must be considered

end system

exit unit to unload

tubes from output tray to blowing system and final storage with rate

one tube each 2.5 sed.

start position must be considered

performance

performance of

machines is 24 tube per minute regardless tube diameter or length.

diameters starts from 1/2 inch to 4 inches

length up to 6 m

dipping

system

dipping system to

immerse tubes inclined in zinc container with rate one tube each 2.5

sec.

always there are one tube in zinc plus one in and one out

zinc container

zinc container to be

130 cm width, 6 m length and 100 cm above ground level.

space available up to 390 cm width and 105 cm high with unlimited

length

blowing system

blowing system tol

blow steam into tube from one end and return it from other end

it acts as tube clamp during blowing

water tank

water tank to be 130

cm width, 6 m length and 100 cm above groun level.

space available up to 390 cm width and 105 cm high with unlimited

length

cleaning system

air cleaning system

uses hot air or steam to clean excess zinc and water just after zinc

and water containers

air nozzles are directed to tubes during rolling

blowing system

blowing system tol

blow air into tube from one end and return it from other end

it acts as tube clamp during blowing

|